Both air-cooled and liquid-cooled energy storage systems (ESS) are widely adopted across commercial, industrial, and utility-scale applications. But their performance, operational cost, and risk profiles differ significantly.

This blog breaks down the differences so you can confidently choose the right cooling method for your next ESS project.

Air Cooling vs. Liquid Cooling: Two Paths to Thermal Stability

As the energy storage sector surges forward in 2025, thermal management has become a non-negotiable element of system safety and performance. Recent high-profile incidents underscore the risks of inadequate cooling:

In early 2025, the Moss Landing Energy Storage Facility in the U.S. experienced its fourth fire due to partial failure in its air-cooled system, destroying 70% of the equipment.

A liquid-cooled system leak at a German industrial site triggered a fire, halting production for 12 hours and resulting in direct losses exceeding €2 million.

The message is clear: choosing the right battery cooling system isn’t just a design decision—it’s a safety, performance, and financial imperative.

1. How These Two Battery Cooling Systems Work

Air-Cooled Energy Storage Systems

Cost-Effective and Easy to Deploy

Air cooling uses fans or air conditioners to circulate air around battery cells. It’s simple and proven.

Advantages:

Lower initial cost

Simple design and maintenance

Flexible for small and mid-sized deployments

Ideal for:

Rooftop solar + storage

Small commercial buildings

Quick-deployment microgrids

Lithium Valley Products:

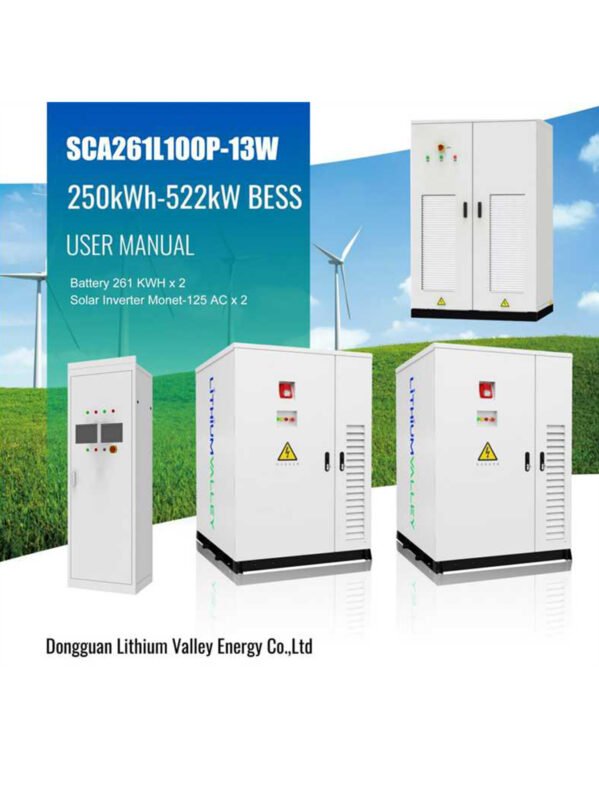

SC143A50P-06W – 50kW / 143kWh: Compact, outdoor-ready, modular

SCA215A100-01M – 100kW / 215kWh: Integrated solution for light commercial use

Liquid-Cooled Energy Storage Systems

Precision Cooling for High-Capacity Demands

Liquid cooling uses a closed-loop fluid circuit to extract heat from battery modules with much higher accuracy and efficiency.

Advantages:

±2°C temperature precision

Higher energy density and compact footprint

Longer battery lifespan

Ideal for:

Industrial facilities

Utility-scale ESS

High-frequency cycling and long-duration energy storage

Lithium Valley Products:

MV1290-2500H-05G – 1290kW / 2507kWh: All-in-one cabinet for grid or islanded systems

MV500-1000L-05G – 500kW / 1044.9kWh: Modular, scalable up to 5MWh+

2. Which Cooling System Fits Your Project?

| Use Case | Recommended Cooling |

|---|---|

| Rooftop Solar + Storage | ✅ Air-Cooled |

| Retail & Office Buildings | ✅ Air-Cooled |

| Industrial Parks & Factories | ✅ Liquid-Cooled |

| Utility-Scale & Grid Services | ✅ Liquid-Cooled |

Each scenario demands a tailored approach. Thermal strategy should align with system size, climate, load profile, and lifecycle cost.

3. Performance Showdown: Air vs. Liquid Cooling in ESS

Thermal Precision & Battery Life

Air Cooling: Susceptible to hot spots, especially under high ambient temperatures.

Liquid Cooling: Maintains even thermal distribution, extends battery life by 30% or more.

Operation & Maintenance (O&M)

Air Cooling: Lower complexity, but HVAC power draw rises in summer or high-load conditions.

Liquid Cooling: Requires fluid checks and leak prevention, but offers better long-term efficiency.

Space Utilization & Safety

Air Cooling: No fluid circulation, fewer leak-related risks.

Liquid Cooling: Compact, high power density systems; requires robust sealing and corrosion protection.

4. Industry Trends: The Rise of Liquid Cooling

With larger systems and higher cycling demands, liquid cooling is rapidly becoming the mainstream choice for projects over 1MWh or 500kW.

That said, air cooling still dominates in smaller, distributed, and budget-conscious scenarios—thanks to its affordability, simplicity, and ease of deployment.

Trend Insight:

Analysts project liquid-cooled ESS to dominate new installations after 2025, especially in long-duration storage, industrial peak shaving, and utility grid services.

5. Comparison Table: Quick View

| Attribute | Air-Cooled ESS | Liquid-Cooled ESS |

|---|---|---|

| Cooling Method | Fans / HVAC | Liquid circulation |

| Temp Control Accuracy | Moderate | High (±2°C) |

| Power Range | 50–125kW | 250–1290kW |

| O&M Complexity | Low | Moderate to High |

| Upfront Cost | Lower | Higher |

| Best For | PV + Storage, Offices, Microgrids | Grid-scale, Industry, Long-duration storage |

Conclusion: Choose Cooling Based on Application—Not Hype

The debate between air-cooled vs. liquid-cooled energy storage is not about “better vs. worse.” It’s about fit-for-purpose engineering.

Air-cooled systems offer a lower-cost, easier-to-maintain option for small to medium-sized applications.

Liquid-cooled systems are essential for high-performance, high-density, and long-duration storage needs.

At Lithium Valley, We Engineer Cooling That Fits

As a global leader in energy storage solutions, Lithium Valley offers both air and liquid-cooled ESS options, designed with safety, performance, and scalability in mind.

Whether you’re deploying a 100kW commercial system or a 100MWh grid-scale project, we help you select the right battery thermal management system to maximize value and minimize risk.

.png)

.png)

.png)

.png)